Trucks Scales

- By maple scales

- July 17, 2025

- Accecories

CHOOSING THE SCALE-On the surface or pit

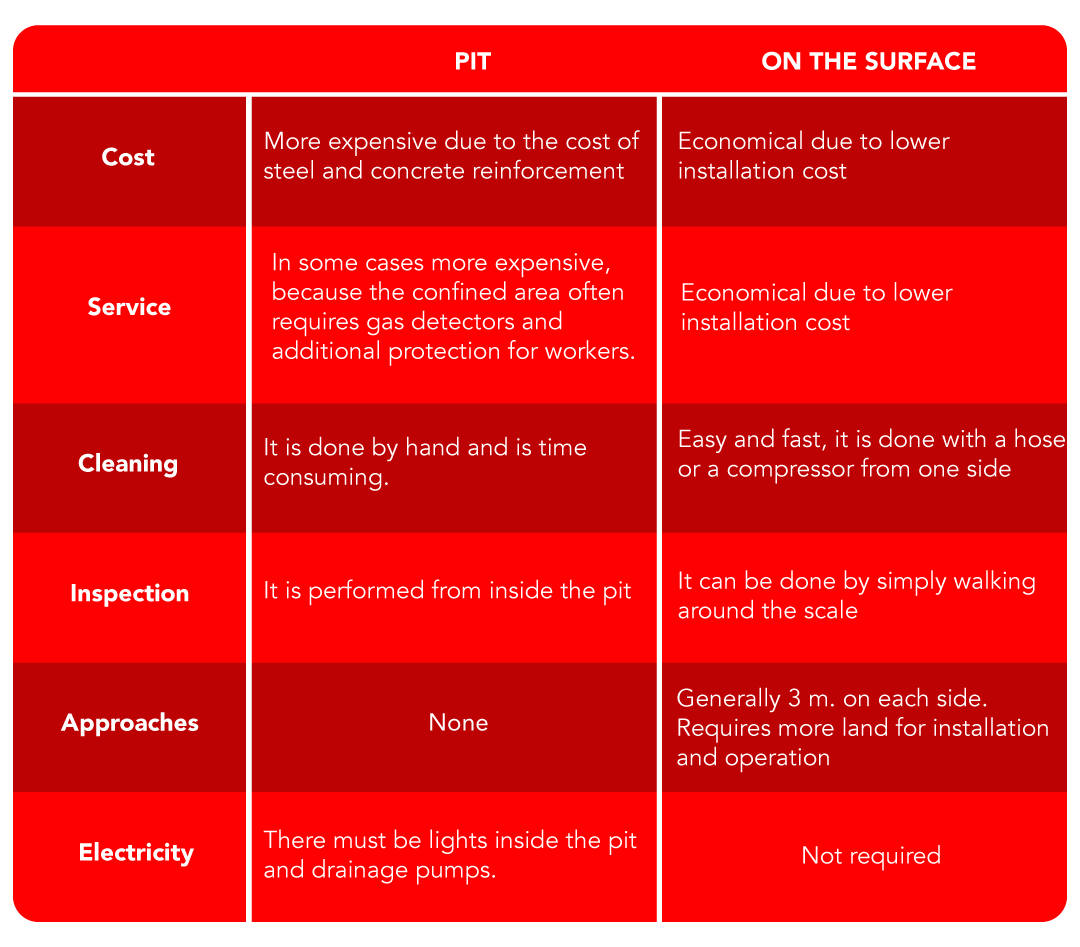

Until the 1970s, all scales were mechanical and installed in inexpensive concrete pits. Now, most scales are installed above ground or in shallow pits. With new modular construction techniques, scales can also be installed on uneven floors. One of the most important reasons for choosing a pit model is space or lack thereof. A pit installation requires less space than an above-ground installation due to the close proximity to the scale. However, pit scales require, in addition to a greater investment in the pit, pumps, and very marked positive drainage and are more prone to accelerated corrosion and rusting due to the presence of water in the pit.

Your truck scale is a cash register

Products for production come into your plant and finished products leave it, so having reliable and accurate control is essential to the success of your operation.

A truck scale is long-term investment that, with proper care, will easily give you 25 years of service.

There are many options in the truck scale market and, to the casual observer, the

initial purchase price may be the only difference.

However, manufacturers who offer great deals or discounts can do so at the

cost of quality in the process, whether it be design, materials, components, finish

or all of the above.

While the price may be attractive initially, eventual failure due to poor

quality in your truck scale can mean a very high cost, whether downtime, high maintenance costs, or lost revenue.

The differences between a truck scale of exceptional quality and low-priced models are not always

apparent at first glance. Unfortunately, critical differences are not noticeable until

too late.

Maple has created this document to help you identify the characteristics of a truck scale that substantially affect the performance and longevity

of your investment.

A truck scale is long-term investment that, with proper care, will easily give you 25 years of service.

There are many options in the truck scale market and, to the casual observer, the

initial purchase price may be the only difference.

However, manufacturers who offer great deals or discounts can do so at the

cost of quality in the process, whether it be design, materials, components, finish

or all of the above.

While the price may be attractive initially, eventual failure due to poor

quality in your truck scale can mean a very high cost, whether downtime, high maintenance costs, or lost revenue.

The differences between a truck scale of exceptional quality and low-priced models are not always

apparent at first glance. Unfortunately, critical differences are not noticeable until

too late.

Maple has created this document to help you identify the characteristics of a truck scale that substantially affect the performance and longevity

of your investment.

THE RIGHT FOUNDATION-On the surface or pit

The foundation is one of the most important parts of your scale.

If it is not built properly, level, and horizontally, and according to the certified construction plan, the foundation can move and take the scale out of acceptable calibration tolerances.

If the movement continues the scale will become inoperable and require very expensive repairs.

Many factors must be considered in the process, such as the slope of the site and the conditions of the ground, a soil mechanics is necessary before deciding on the type of scale to install and to choose the reinforcement of the civil work.

Approaches and Ramps:

According to legal regulations for buying and selling, the approaches to the scale must be

on the surface, at least 3 meters wide, the width of the scale, and built of concrete, leveled and

flat.

The ramps plus the approaches must be at least half the length of the scale.

A 21-meter scale must have a minimum of 3 meters of ramps and the approaches of

7.5 meters.

This is 10.50 meters long.

Equivalent to 42.50 meters needed for a 21-meter scale.

If it is not built properly, level, and horizontally, and according to the certified construction plan, the foundation can move and take the scale out of acceptable calibration tolerances.

If the movement continues the scale will become inoperable and require very expensive repairs.

Many factors must be considered in the process, such as the slope of the site and the conditions of the ground, a soil mechanics is necessary before deciding on the type of scale to install and to choose the reinforcement of the civil work.

Approaches and Ramps:

According to legal regulations for buying and selling, the approaches to the scale must be

on the surface, at least 3 meters wide, the width of the scale, and built of concrete, leveled and

flat.

The ramps plus the approaches must be at least half the length of the scale.

A 21-meter scale must have a minimum of 3 meters of ramps and the approaches of

7.5 meters.

This is 10.50 meters long.

Equivalent to 42.50 meters needed for a 21-meter scale.

THE LOAD BRIDGE - Concrete and Steel?

The foundation is one of the most important parts of your scale.

If it is not built properly, level, and horizontally, and according to the certified construction plan, the foundation can move and take the scale out of acceptable calibration tolerances.

If the movement continues the scale will become inoperable and require very expensive repairs.

Many factors must be considered in the process, such as the slope of the site and the conditions of the ground, a soil mechanics is necessary before deciding on the type of scale to install and to choose the reinforcement of the civil work.

Approaches and Ramps:

According to legal regulations for buying and selling, the approaches to the scale must be

on the surface, at least 3 meters wide, the width of the scale, and built of concrete, leveled and

flat.

The ramps plus the approaches must be at least half the length of the scale.

A 21-meter scale must have a minimum of 3 meters of ramps and the approaches of

7.5 meters.

This is 10.50 meters long.

Equivalent to 42.50 meters needed for a 21-meter scale.

If it is not built properly, level, and horizontally, and according to the certified construction plan, the foundation can move and take the scale out of acceptable calibration tolerances.

If the movement continues the scale will become inoperable and require very expensive repairs.

Many factors must be considered in the process, such as the slope of the site and the conditions of the ground, a soil mechanics is necessary before deciding on the type of scale to install and to choose the reinforcement of the civil work.

Approaches and Ramps:

According to legal regulations for buying and selling, the approaches to the scale must be

on the surface, at least 3 meters wide, the width of the scale, and built of concrete, leveled and

flat.

The ramps plus the approaches must be at least half the length of the scale.

A 21-meter scale must have a minimum of 3 meters of ramps and the approaches of

7.5 meters.

This is 10.50 meters long.

Equivalent to 42.50 meters needed for a 21-meter scale.

THE LOADING BRIDGE OF SUPERIOR QUALITY

A big consideration when selecting a truck scale is whether to choose a steel or concrete loading bridge. Both have their advantages. Here are some features of each that will help you choose the right type of loading bridge.

The structural integrity of the loading bridge is the most important consideration when purchasing a truck scale. A buckling or warping loading bridge results in ongoing problems that can only be resolved by replacing the truck scale. All of our models are guaranteed for 10 years on the loading bridge ensuring the integrity of your investment.

Some manufacturers use lighter steel in their scales to reduce the cost of the scale, but over time these models warp causing inaccurate weighing, lost repair time, and eventually complete failure. Our models are manufactured by weight, meaning that each scale is perfectly rated to withstand the load it is manufactured for. We use the most modern manufacturing techniques ensuring that each piece is of the highest quality.

The cast concrete bridge incorporates the most modern design in the reinforcement structure that ensures that the concrete remains above the neutral axis of the bridge. Some low-cost models have the concrete under the neutral axis of the weighbridge, this increases the stress causing the bridge to

crack and eventually leading to the collapse of the weighbridge.

The structural integrity of the loading bridge is the most important consideration when purchasing a truck scale. A buckling or warping loading bridge results in ongoing problems that can only be resolved by replacing the truck scale. All of our models are guaranteed for 10 years on the loading bridge ensuring the integrity of your investment.

Some manufacturers use lighter steel in their scales to reduce the cost of the scale, but over time these models warp causing inaccurate weighing, lost repair time, and eventually complete failure. Our models are manufactured by weight, meaning that each scale is perfectly rated to withstand the load it is manufactured for. We use the most modern manufacturing techniques ensuring that each piece is of the highest quality.

The cast concrete bridge incorporates the most modern design in the reinforcement structure that ensures that the concrete remains above the neutral axis of the bridge. Some low-cost models have the concrete under the neutral axis of the weighbridge, this increases the stress causing the bridge to

crack and eventually leading to the collapse of the weighbridge.

COMPONENTS-HMN digital weight indicators

We have a wide variety of weight indicators, to be used

with the weight program without an identifier through the indicator, and for

use of the same program but with identification and printing capacity.

Model 355 indicator made of NEMA 4X stainless steel with capacity of 6 LED digits of 20.3 mm height with 2

communication ports and configurable from a computer.

Indicator 710 with full alphanumeric keyboard for identification, with

memory of 300 trucks, with long digits of 19 mm VFD, five

linearization points in calibration and programming by computer, 2 RS232 communication ports, one RS485 and a printing port.

For 100% digital applications we have two weight indicators,

the 810i and the 920i both connect to the iQUBE digital summing box

that allows complete control with the most modern electronic equipment

and state-of-the-art digital indicator.

The scale diagnosis is displayed on the indicator in real time,

alerting the operator about possible errors and conditions outside of normal

operation. It uses two basic algorithms for the operation of load cells and their calibration:

-The Cell-Emulator algorithm is used to allow the operation of the scale

even when a repair of the load cells is required.

-The Cal-Match algorithm automatically calibrates the scale with a single

pass of the standard weights (in each corner of the scale or section).

It does not require immediate calibration when changing damaged load cells.

It offers the possibility of calibrating the scale without the use of standard tare weights.

It uses analog load cells, therefore it does not require digital load cells.

This represents a great saving in maintenance costs.

Alerts are sent via Ethernet to the user and the manufacturer (optional Ethernet card). Optional connection based on fiber optics in a network.

with the weight program without an identifier through the indicator, and for

use of the same program but with identification and printing capacity.

Model 355 indicator made of NEMA 4X stainless steel with capacity of 6 LED digits of 20.3 mm height with 2

communication ports and configurable from a computer.

Indicator 710 with full alphanumeric keyboard for identification, with

memory of 300 trucks, with long digits of 19 mm VFD, five

linearization points in calibration and programming by computer, 2 RS232 communication ports, one RS485 and a printing port.

For 100% digital applications we have two weight indicators,

the 810i and the 920i both connect to the iQUBE digital summing box

that allows complete control with the most modern electronic equipment

and state-of-the-art digital indicator.

The scale diagnosis is displayed on the indicator in real time,

alerting the operator about possible errors and conditions outside of normal

operation. It uses two basic algorithms for the operation of load cells and their calibration:

-The Cell-Emulator algorithm is used to allow the operation of the scale

even when a repair of the load cells is required.

-The Cal-Match algorithm automatically calibrates the scale with a single

pass of the standard weights (in each corner of the scale or section).

It does not require immediate calibration when changing damaged load cells.

It offers the possibility of calibrating the scale without the use of standard tare weights.

It uses analog load cells, therefore it does not require digital load cells.

This represents a great saving in maintenance costs.

Alerts are sent via Ethernet to the user and the manufacturer (optional Ethernet card). Optional connection based on fiber optics in a network.

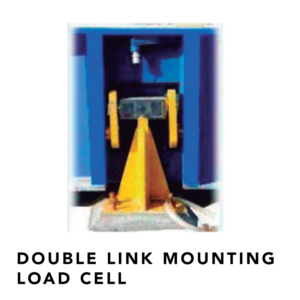

COMPONENTS-Load Cells

We have two models of load cells, double link with a capacity of 65,000 pounds each

One is made of nickel-plated steel, which is the traditional and most used system. We incorporated this system for the first time 40 years ago when we installed the first surface scale in Latin

America. This cell uses the assembly that allows the free movement of the loading bridge when a truck enters the scale and it self-aligns until it is in its optimal position. It is recommended

for high capacities, it is a very reliable and safe model.

The 30-ton capacity compression load cell model is primarily used for pit scales due to its laser-sealed stainless steel construction. This load cell is highly resistant to corrosion and uses a mount that is positioned more directly under the loading bridge. Both load cells and mounting systems have the same accuracy and come with the same 2-year warranty against any manufacturing defects. You can choose either of these two load cell models when making your BASSAA truck scale selection.

One is made of nickel-plated steel, which is the traditional and most used system. We incorporated this system for the first time 40 years ago when we installed the first surface scale in Latin

America. This cell uses the assembly that allows the free movement of the loading bridge when a truck enters the scale and it self-aligns until it is in its optimal position. It is recommended

for high capacities, it is a very reliable and safe model.

The 30-ton capacity compression load cell model is primarily used for pit scales due to its laser-sealed stainless steel construction. This load cell is highly resistant to corrosion and uses a mount that is positioned more directly under the loading bridge. Both load cells and mounting systems have the same accuracy and come with the same 2-year warranty against any manufacturing defects. You can choose either of these two load cell models when making your BASSAA truck scale selection.

ACCESSORIES- Digital weight indicators

We have several ticket printers that connect directly to the communication port of the weight indicators and can be configured to print the necessary data.

The truck scale is the center of your operation and can be added with accessories and various options such as remote displays that show the weight clearly visible on the outside with LED digits up to 6 inches high.

The truck scale is the center of your operation and can be added with accessories and various options such as remote displays that show the weight clearly visible on the outside with LED digits up to 6 inches high.

COMPONENTS-Load Cells

• The client will carry out the civil work according to the plans provided by Maple.

• The physical ground must be placed at a depth of 6 meters. Copper bar sunk with clamp

on the surface where the cable is fastened according to the specifications of the civil work plans.

• It is requested that a crane or forklift be available for unloading and handling the scale bridge on the day of arrival and at the installation with a capacity of 3 tons of load.

• On the day of installation of the weighing equipment, 2 laborers will be required at the client's expense to

help with the maneuvers.

• The electrical installation must be independent for the weighing equipment.

• The current must be regulated.

• The power outlets must be placed at a distance of one meter from the equipment.

• For the installation of truck weighing equipment, a fully finished booth is required where the digital weight indicator with windows and doors will be installed.

• The client is required to provide an individual polarized contact 110/120 VAC (live, neutral, ground).

The electrical installation must be dedicated to the digital weight indicator.

• Supervision, installation and start-up is considered to take 3-4 days in

2 or 3 stages.

• The client will provide 4 assistants for the installation in the 1st and 2nd stages and 3 assistants in the3rd stage.

• The client will provide a crane for unloading maneuvers and assembly of the loading bridge.

• For the initial calibration of the weighing equipment, the client must provide a known weight.

• It is very important to install appropriate physical ground to protect the electronic equipment from

electric discharges that protect up to 5 meters in height and around the weighing equipment up to 5 meters.

1st visit

Assembling the bridge

The client performs the casting of the

bearing slab

2nd visit

Installation of mounts, load cells, wiring, electronic equipment, start-up and weight adjustment

Suggestions to the customer for the

conservation of their equipment:

-Installation of a lightning rod

-Installation of a bypass to the load cells

• The physical ground must be placed at a depth of 6 meters. Copper bar sunk with clamp

on the surface where the cable is fastened according to the specifications of the civil work plans.

• It is requested that a crane or forklift be available for unloading and handling the scale bridge on the day of arrival and at the installation with a capacity of 3 tons of load.

• On the day of installation of the weighing equipment, 2 laborers will be required at the client's expense to

help with the maneuvers.

• The electrical installation must be independent for the weighing equipment.

• The current must be regulated.

• The power outlets must be placed at a distance of one meter from the equipment.

• For the installation of truck weighing equipment, a fully finished booth is required where the digital weight indicator with windows and doors will be installed.

• The client is required to provide an individual polarized contact 110/120 VAC (live, neutral, ground).

The electrical installation must be dedicated to the digital weight indicator.

• Supervision, installation and start-up is considered to take 3-4 days in

2 or 3 stages.

• The client will provide 4 assistants for the installation in the 1st and 2nd stages and 3 assistants in the3rd stage.

• The client will provide a crane for unloading maneuvers and assembly of the loading bridge.

• For the initial calibration of the weighing equipment, the client must provide a known weight.

• It is very important to install appropriate physical ground to protect the electronic equipment from

electric discharges that protect up to 5 meters in height and around the weighing equipment up to 5 meters.

1st visit

Assembling the bridge

The client performs the casting of the

bearing slab

2nd visit

Installation of mounts, load cells, wiring, electronic equipment, start-up and weight adjustment

Suggestions to the customer for the

conservation of their equipment:

-Installation of a lightning rod

-Installation of a bypass to the load cells